Languages

Bag Filter

(1) Reverse Air Fabric Filter

- Suitable for large facilities (range: 1,500~100,000m3/min)

- Low air to cloth ratios

- Simple design with few moving parts

- Easy maintenance

- Compartment ventilation during maintenance

(2) Pulse Jet Air Fabric Filter

- Wide variety of applications (range: 50~25,000m3/min)

- Bags are kept on the clean side, eliminating the need for ventilation during maintenance

- High air to cloth ratios

- Less space required for installation

Projects

- Danyang Plant, Sungshin Cement, Korea (2002)

- Retrofit Pohang Limestone calcination Plants 1~2, POSCO, Korea

- Yeongwol Plant , Ssangyong Cement, Korea (2003)

- Pohang Steel Plant 2, POSCO, Korea (2003)

- Gwangyang Sintering Plants 1~ 4, POSCO, Korea (2005)

- Asia Special Steel Plant, Japan (2008)

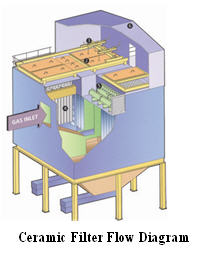

(3) Ceramic Filters

Ceramic filters boasts reliability and high efficiency and can trap dust at temperatures above 250°C, which has been regarded as the critical temperature for conventional fabric filters. Because it functions at high temperatures, there is no need for a flame prevention system, spark prevention device, cooler, or spraytower. Ceramic filter also leads to energy and water savings.

Ceramic filters can be used even at a temperature of 900°C and shows high

filtration efficiency against fine particles. In addition, it has resistance to sparks, incandescent particles, and accidental flame. The Ceramic filters are resistant to acid and alkaline corrosion and do not require a lot of space as air dilution is not necessary.

1. Easily removed access doors for maintenance

1. Easily removed access doors for maintenance

2. Trolley

3. Ceramic filter elements

4. Pulsed cleaning system

5. Optional weatherproof tophousing

Advantages

- NaHCO3 and slaked lime injected as sorbents for HCL and

SO2 removal

- Enhanced dioxin ratio

- Integration with optimal dust removal system lengthens catalyst lifespan and removes the need to reheat gas

- Can be used in Heat recovery Plant

- Greater efficiency throughout entire process

1. Easily removed access doors for maintenance

2. Trolley

3. Ceramic filter elements

4. Pulsed cleaning system

5. Optional weatherproof tophousing

Advantages

- NaHCO3 and slaked lime injected as sorbents for HCL and

SO2 removal

- Enhanced dioxin ratio

- Integration with optimal dust removal system lengthens catalyst lifespan and removes the need to reheat gas

- Can be used in Heat recovery Plant

- Greater efficiency throughout entire process